Sodium Silicate

Home > China Clay Powder

Sodium Silicate Manufacturers in India

Surendra Enterprises is a prominent Sodium Silicate Manufacturer in India, producing tons of high-quality Sodium Silicate annually. Our state-of-the-art facilities ensure the production of top-grade Sodium Silicate, a versatile material widely used in various industries including detergents, adhesives, construction, water treatment, foundry, and textiles.

With our advanced production capabilities and access to premium raw materials, we offer highly competitive prices without compromising on quality. Renowned as one of the leading Sodium Silicate manufacturers in India, we also cater to international markets through our reliable export services.

Surendra Enterprises has established itself as a key player in the global market, recognized for our commitment to quality and consistency in both national and international sectors. We take pride in being at the forefront of Sodium Silicate manufacturing in India, ensuring premium quality and reliability in every batch.

Sodium Silicate, also known as water glass, is an alkaline compound with the chemical formula Na₂SiO₃. It is produced through a high-temperature reaction between silica sand and soda ash. The resulting compound is water-soluble and offers excellent adhesive and binding properties, making it highly valuable across multiple industrial applications.

Trust Surendra Enterprises for high-quality Sodium Silicate products tailored to meet the diverse needs of various industries. Experience the difference with Surendra Enterprises – where quality meets reliability.

What is Sodium Silicate?

Sodium Silicate, also known as water glass, is an alkaline compound derived from a combination of sodium carbonate (soda ash) and silica sand. It is one of the most versatile chemicals, widely used across various industries due to its unique chemical and physical properties.

Sodium Silicate is produced through a high-temperature fusion process where silica and soda ash are melted together, resulting in a water-soluble glass-like compound. Its chemical formula is typically represented as Na₂SiO₃. This composition imparts properties such as strong adhesive strength, excellent binding ability, and resistance to high temperatures and chemicals.

Due to its remarkable versatility, Sodium Silicate finds extensive application in detergents, adhesives, construction, water treatment, foundries, paper, ceramics, and textiles. In the detergent industry, it acts as a binding agent and corrosion inhibitor, while in construction, it is used as a sealant and concrete hardener.

In water treatment processes, Sodium Silicate serves as a coagulating agent, enhancing water purification. Its role in foundries as a binding agent for molds and cores highlights its industrial significance.

With its excellent adhesive properties, thermal stability, and chemical resilience, Sodium Silicate continues to play a critical role in enhancing product performance and industrial efficiency.

Specifications

| China Clay Powder | |

| SiO₂ Content: | 28% to 30% |

| Na₂O Content: | 8% to 10% |

| SiO₂:Na₂O: | 2.0 to 3.3 |

| Density: | 1.4 to 1.6 g/cm³ |

| pH Value: | 11 to 12.5 |

| Mgo | 0.5% Max |

| Viscosity: | 20 to 600 mPa·s |

| Solubility: | Completely soluble in water |

| Form: | Liquid / Powder |

| Boiling Point: | Above 100°C |

| Melting Point: | 1,088°C |

| Appearance: | Clear, colorless to slightly hazy liquid or white solid |

| Mesh Size: | 200 to 400 Mesh |

Applications and Uses of Sodium Silicate

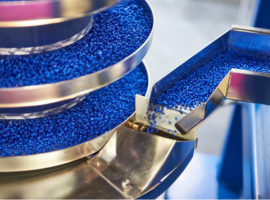

Plastic Processing

Detergent Grade

Medical Industries

Rubber Industries

Paper Manufacturing

Paint Production

Properties of Sodium Silicate:-

1. Chemical Formula: Na₂SiO₃

2. Appearance: Transparent or translucent glass-like solid; available in liquid or powdered forms.

3. Molecular Weight: Varies depending on the ratio of Na₂O to SiO₂ (common ratio: 1:2 to 1:3.75).

4. Solubility: Highly soluble in water, forming an alkaline solution.

5. pH: Typically ranges from 11 to 12.5 in aqueous solutions.

6. Density: 1.4 – 1.6 g/cm³ (depending on concentration and form).

7. Viscosity: Varies based on SiO₂/Na₂O ratio and temperature; higher ratios result in increased viscosity.

8. Melting Point: Around 1,088°C (1,990°F) for solid sodium silicate.

9. Alkalinity: Highly alkaline, making it reactive with acids to form silica gel.

10. Thermal Stability: Stable at high temperatures; used in refractory applications.

11. Adhesive Property: Excellent binding properties; widely used in adhesives, cements, and coatings.

12. Corrosion Resistance: Provides protection against corrosion in certain industrial processes.