MG/CA/ZN Manufacturers

Home > China Clay Powder

MG/CA/ZN Manufacturers in India

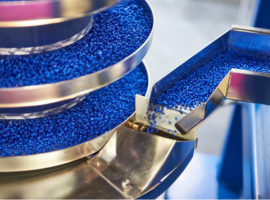

Surendra Enterprises is a prominent manufacturer of Magnesium Stearate (Mg Stearate), Calcium Stearate (Ca Stearate), and Zinc Stearate (Zn Stearate) in India, producing large volumes of these premium products annually. Our state-of-the-art facilities and advanced technology ensure the consistent production of high-quality stearates, which are essential in various industries such as pharmaceuticals, cosmetics, food, plastics, and more.

With our modern production capabilities and access to high-quality raw materials, we are able to offer these stearates at highly competitive prices while ensuring premium quality. Renowned as leading stearate manufacturers in India, we also serve international markets through our extensive export network.

Surendra Enterprises has established itself as a key player in the global market, recognized for our dedication to excellence and customer satisfaction. We take pride in being at the forefront of stearate manufacturing in India, ensuring that every batch adheres to the highest quality standards.

Magnesium Stearate (Mg Stearate), Calcium Stearate (Ca Stearate), and Zinc Stearate (Zn Stearate) are produced using top-quality raw materials and undergo rigorous processing to remove impurities. These stearates are used as lubricants, stabilizers, and release agents in a wide range of applications, including in the pharmaceutical industry for tablet manufacturing, in cosmetics for smooth texture, and in plastics and rubber for improved processing.

Trust Surendra Enterprises for high-quality Magnesium Stearate, Calcium Stearate, and Zinc Stearate products that meet the diverse needs of industries worldwide. Experience the difference with Surendra Enterprises – where quality and reliability come together.

What is MG/CA/ZN Manufacturers?

Magnesium Stearate (Mg Stearate), Calcium Stearate (Ca Stearate), and Zinc Stearate (Zn Stearate) are fine, white powders widely used across various industries due to their excellent properties as lubricants, stabilizers, and release agents.

These stearates are derived from the reaction of their respective metal salts (magnesium, calcium, and zinc) with stearic acid. They are produced through a process of neutralizing metal salts with stearic acid, forming the desired stearate compounds. Their chemical structure, based on long-chain fatty acids, gives them unique properties, including high thermal stability, low friction, and excellent water-repellence.

Due to their versatile and desirable properties, Magnesium Stearate, Calcium Stearate, and Zinc Stearate find widespread applications in industries such as pharmaceuticals, cosmetics, food processing, plastics, and rubber. In the pharmaceutical industry, these stearates are used as lubricants in tablet and capsule formulations to prevent sticking and improve flow properties. In the cosmetics industry, they enhance texture and act as dispersing agents in powders and creams. Additionally, in the plastics and rubber industries, they improve the processing and release properties of materials.

These stearates are highly valued for their ability to improve the efficiency and quality of various products, contributing to smoother processing and a higher standard of performance across different manufacturing sectors.

Applications and Uses of MG/CA/ZN Manufacturers

Plastic Processing

Detergent Grade

Medical Industries

Rubber Industries

Paper Manufacturing

Paint Production

Properties of MG/CA/ZN Manufacturers:-

1.

Chemical Composition:

- Magnesium Stearate (Mg Stearate): Composed of magnesium ions and stearic acid (C18H36O2).

- Calcium Stearate (Ca Stearate): Composed of calcium ions and stearic acid.

- Zinc Stearate (Zn Stearate): Composed of zinc ions and stearic acid.

2.

Color and Texture:

- All three stearates are fine, white powders with a smooth and uniform texture. Variations in color and texture may occur based on purity levels and processing methods.

3.

Lubricity:

- Magnesium Stearate, Calcium Stearate, and Zinc Stearate are well-known for their excellent lubricating properties, which reduce friction in processing operations, enhancing the performance of materials in industries such as pharmaceuticals, plastics, and cosmetics.

4.

Solubility:

- All three stearates are insoluble in water but are soluble in organic solvents such as chloroform, ether, and benzene. This makes them effective in formulations that require moisture resistance.

5.

Thermal Stability:

- Magnesium Stearate, Calcium Stearate, and Zinc Stearate are thermally stable and can withstand high temperatures during industrial processes without degrading, making them suitable for use in a variety of manufacturing environments.

6.

Flowability:

- These stearates significantly improve the flowability of powder-based materials, which is essential in the pharmaceutical, cosmetic, and plastics industries. This enhances the ease of processing and handling.

7.

Water Resistance:

- All three stearates exhibit high water resistance, making them ideal for use in water-sensitive applications such as paints, coatings, and cosmetics.

8.

pH Level:

- Magnesium Stearate, Calcium Stearate, and Zinc Stearate have slightly alkaline pH levels, making them stable in formulations without significantly altering the chemical balance of other ingredients.

9.

Binder and Filler:

- These stearates are used as binders and fillers in various industries, enhancing product strength, stability, and consistency. They are especially valuable in tablet manufacturing, rubber processing, and plastic formulations.

10.

Use in Cosmetics and Pharmaceuticals:

- Magnesium Stearate is commonly used as a lubricant in tablet formulations, ensuring smooth tablet compression and preventing sticking. Calcium Stearate and Zinc Stearate also play essential roles in the cosmetic industry, serving as emulsifiers, stabilizers, and softening agents.

products.