Bentonite Powder

Home > China Clay Powder

Bentonite Powder Manufacturers in India

Surendra Enterprises is a leading Bentonite Powder manufacturer in India, producing high-quality Bentonite in large quantities. Our advanced facilities ensure the production of top-grade Bentonite, a versatile material widely used in industries such as oil drilling, construction, foundry, and more.

With our modern production capabilities and access to natural resources from petrochemical sources globally, we offer highly competitive prices without compromising on quality. As a prominent Bentonite Powder manufacturer in India, we also cater to international markets through our export services.

Surendra Enterprises has earned a strong reputation in the global market, known for our commitment to excellence in both national and international sectors. We take pride in being a top player in Bentonite manufacturing in India, delivering premium quality and consistency with every batch.

Bentonite, a naturally occurring clay, is primarily composed of montmorillonite and is formed through the alteration of volcanic ash. It has unique properties, such as high absorbency and swelling capacity, making it highly effective in various applications. During processing, impurities such as free silica are carefully removed through specialized techniques such as levigation, sedimentation, and air separation.

Trust Surendra Enterprises for high-quality Bentonite Powder products designed to meet the diverse requirements of multiple industries. Experience the difference with Surendra Enterprises – where quality and reliability come together.

What is China Bentonite Powder?

Bentonite Powder is a fine, highly absorbent clay derived from volcanic ash. It is a naturally occurring clay mineral primarily composed of montmorillonite, and is widely used across various industries due to its versatile properties.

Bentonite Powder is formed through the alteration of volcanic ash, which undergoes weathering and chemical processes. The mineral’s unique composition, particularly its high swelling and absorption capacities, makes it ideal for a variety of applications. Its chemical structure and properties enable it to retain moisture and form thick pastes, making it effective in numerous industrial processes.

Thanks to its remarkable properties, Bentonite Powder is used in several industries, including oil drilling, construction, foundry, and environmental protection. In the oil and gas industry, Bentonite Powder is primarily used in drilling fluids to lubricate drill bits and help control pressure. In construction, it is used as a sealant and in the manufacturing of cement. Its ability to absorb toxins and act as a natural binder also makes it valuable in the production of cat litter, cosmetics, and pharmaceutical products.

With its diverse applications and beneficial properties, Bentonite Powder is essential in enhancing the efficiency and quality of various industrial processes.

Specifications

| China Clay Powder | |

| Sio2 | 55% to 60% |

| Al2o3 | 12% to 18% |

| Fe2o3 | 2% Max |

| Tio2 | 1% Max |

| Cao | 1.5% Max |

| Mgo | 1% Max |

| LOI | 10% to 15% |

| Acid Insoluble | 95% to 98% |

| PH | 7.5 to 9.5 |

| B.D. | 0.7 gm/cc |

| Oil absorption | 40 to 45 ml/100 gm |

| Whiteness | 60% to 75% |

| Mesh | Lumps/Powder (200 to 400 Mesh) |

Applications and Uses of Bentonite Powder

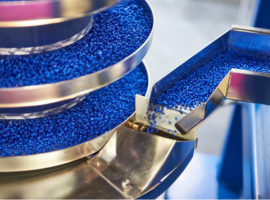

Plastic Processing

Detergent Grade

Medical Industries

Rubber Industries

Paper Manufacturing

Paint Production

Properties of Bentonite Powder:-

1. High Swelling Capacity: Bentonite powder can expand many times its original volume when it absorbs water, making it ideal for applications requiring thickening, gelling, and water retention.

2. Absorbent: Bentonite has excellent absorbent properties, making it effective for use in applications like oil drilling and wastewater treatment.

3. Plasticity: It has good plasticity, which improves its workability in various applications, including ceramics and foundry molding.

4. Viscosity: When mixed with water, Bentonite creates a high-viscosity slurry, which is useful in drilling fluids and as a binder in foundry sands.

5. Cation Exchange Capacity (CEC): Bentonite has a high cation exchange capacity, allowing it to absorb and hold various ions, making it valuable in environmental and agricultural applications.

6. pH Range: Bentonite typically has a pH of 7.5 to 9.5, making it mildly alkaline, which is useful in various industrial and cosmetic products.

7. Chemical Composition: It is mainly composed of montmorillonite (a type of clay mineral), along with other minerals like silica, alumina, and iron oxide.

8. Purity: High-quality Bentonite powder has low impurity levels (such as Fe2O3 and TiO2), contributing to its effectiveness in sensitive applications like food and pharmaceutical industries.

9. Water Retention: Bentonite retains moisture effectively, which is beneficial in agriculture, as it helps improve soil structure and water-holding capacity.

10. Non-toxic and Biodegradable: Bentonite is safe for use in many applications, including cosmetics, food processing, and pharmaceuticals, as it is non-toxic and biodegradable. products.